The PT Boat Forum

http://www.ptboatforum.com/cgi-bin/MB2/netboard.cgi

» Forum Category: PT Boats of WWII

http://www.ptboatforum.com/cgi-bin/MB2/netboard.cgi?cid=101&fct=showf

» Forum Name: PT Boats - General

http://www.ptboatforum.com/cgi-bin/MB2/netboard.cgi?fct=gotoforum&cid=101&fid=102

» Topic:

Chronic PT658 Engine problem

http://www.ptboatforum.com/cgi-bin/MB2/netboardr.cgi?cid=101&fid=102&tid=5083

Hello there! Last Thursday, on 12-2-21 the crew took the recently repaired PT658 out for a "shakedown cruise" of sorts. We tested the Port Engine, which had just had the supercharger drive shaft replaced.

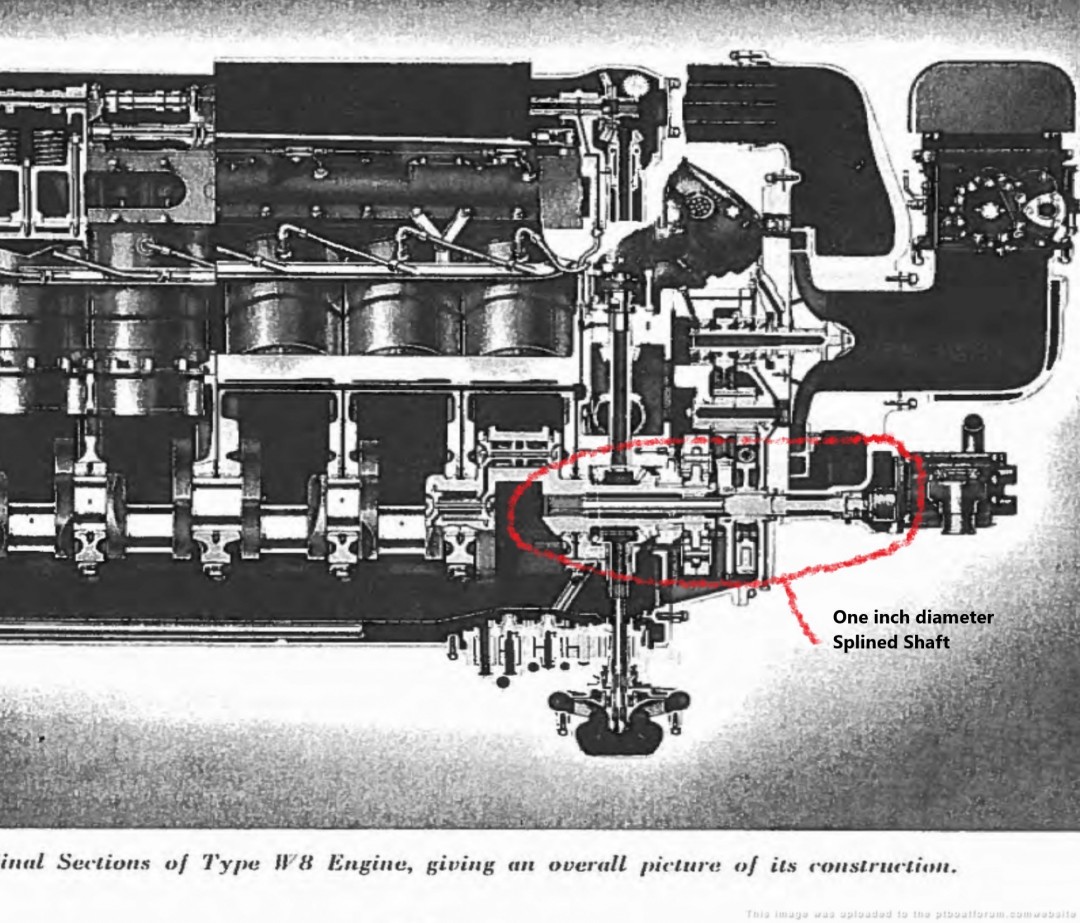

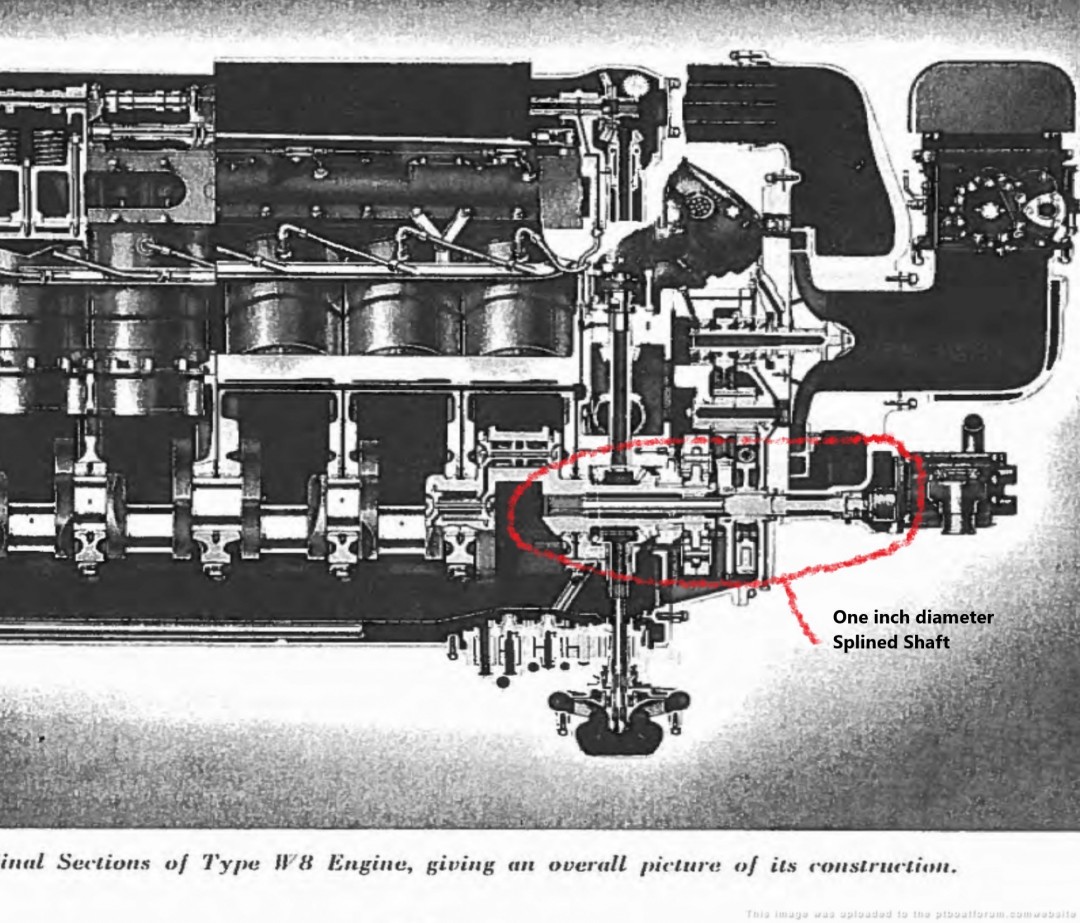

We have had an unfortunate history of breaking supercharger drive shafts! This in itself is sort of mind blowing when you consider this shaft is a 1 inch diameter hardened steel shaft about 12 inches long and splines at both ends. The function of this shaft is to transmit the rotation of the crank shaft into the large central hub of the lower supercharger drive gear. There is an idler gear in between that and the supercharger gear itself which results in a gear ratio of ~6.25:1 for a speed increase of the supercharger wheel in relation to the engine crank shaft.

Our problems started a couple of years ago when we snapped the center engine super drive shaft during an apparent backfire of the engine while starting it. After we disassembled the gear set, we discovered a possible contributing factor (or root cause) of upper engine block internal drilled oil passages were clogged with 60 year old gunk, thus starving the supercharger bearings of lubricating oil. To fix this problem, we flushed the oil passages to remove the old gunk, and then upgraded the old style oil filters to a more modern 1 micron spin-on type oil filter to prevent that same problem from occurring on all 3 engines. OK so now we should be good. WRONG.

So fast forward to last year, and we snapped two more of these same drive shafts! One was for an unknown reason, and this latest one was apparently due to another oil supply issue. We are still trying to take some sort of corrective action but as for now all we can do is keep replacing these irreplaceable supercharger drive shafts! So we are currently in negotiation with a competent machine shop, who has our last remaining spare shaft to use as an example to copy. Does anyone have any ideas or recollections as to why this is happening? We spoke to one of our veterans who has since taken his last patrol on this subject and he said this was a well known "Achilles Heel" of the Packard engines. And before you ask Yes we contacted Randy Smith in New Orleans and he had never heard of this happening with his engines on PT305.

So hopefully somebody on this Forum will hear something or dig up some information about how to prevent this strange failure from happening again! Please let us at PT658 know if you have any solutions. Thanks! Jerry.

Below picture has supercharger drive shaft circled in red connecting the crank shaft to the drive gear.

Jerry Gilmartin

PT658 Crewman

Portland OR

Posted By: Jerry Gilmartin | Posted on: Dec 5, 2021 - 4:10pm

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

Jerry, I have several questions about the problem you are having. If you like we can discuss this over the phone or on the forum which ever you would like.

Where is the shaft breaking?

The replacement shafts are they original or from another v12 for a different application.

Has this happened to all engines or just one.

When you replace the shaft to you flush entire oil system to remove any debris and or metals from the broken shaft?

Do your Packard engines have a hydraulic gear change

arrangement of oil operated clutches to increase the superchargers RPMs kind of like a low and high speed for the supercharger?

Have you checked compression in each cylinder?

Your issue sounds like torsional Vibration.

I found this information about German Engineers looking at our V12 engines used during the war.......

The primary moving components within a V-12 engine power train include the propeller, reduction gears, crankshaft and supercharger drive. These components rotate at relatively high speeds and are driven by the considerable forces coming from combustion gasses via the

pistons and connecting rods. These forces cause intermittent loading and un-loading of the crankshaft journals, which results in non-uniform torsional inputs to the crankshaft, causing it to load-unload at a frequency proportional to the speed of the engine. This variation creates uneven torque impulses on the entire drive train, which being made of high strength steel, twists. This spring-like twisting and un-twisting induces a vibration within all of the

components of the system, which in turn manifests themselves as vibrations. Each of these modes has a natural frequency, determined by the stiffness, configuration and shapes of the materials of construction. Within the mode there are other events occurring, these are vibrations which are multiples of the fundamental natural frequency of the mode and occur at specific crankshaft speeds, or rpm. These orders start at ½ times the

fundamental, and increase in the series 1, 1½, 2, 2½, 3, 3½, 4, 4½, ... Many of these orders have very little energy in them and can be ignored. Some however, often the 4½, 6 and 7½ orders, can be very energetic, and if ignored, can produce stresses that will fatigue and ultimately fracture the metal in the crankshaft or drive element.

-Travis

Posted By: Travis B | Posted on: Dec 5, 2021 - 7:55pm

Total Posts: 129 | Joined: Nov 23, 2019 - 10:11am

This antidote might help! Back in the late 70s, one of the museums in England was restoring a prewar Autounion mid engine V16 supercharged Grand Prix car , the most advanced car in the world when it raced. So they sent a peace of the aluminum engine to Cambridge University for analysis. They sent back a simple note stating, "the sample has all the consistency of good quality lawn furniture!" I would think you could find one of the collages in your area, with a good engineering department, that would love to use one of your junk shafts to analyze and recommend a better material for a learning experience! You could probably get them to do it for free, as a non profit group.

Posted By: Stearman | Posted on: Dec 5, 2021 - 8:16pm

Total Posts: 151 | Joined: Nov 1, 2017 - 9:38pm

Thanks Travis I will list the answers to those questions below.

Q: Where is the shaft breaking?

A: I need to research this one and possibly provide photos of broken shafts. the break is happening in the smaller diameter middle section of the shaft not near the splines

Q: The replacement shafts are they original or from another v12 for a different application?

A: We took our replacement shafts from all of our spare engines. We have a collection of several 4M-2500 Packard V12 PT Boat engines obtained from various places.

Q: Has this happened to all engines or just one?

A: It has happened to the center engine twice and the port engine once

Q: When you replace the shaft to you flush entire oil system to remove any debris and or metals from the broken shaft?

A: Yes the entire oil system including the oil sump was flushed completely and the oil replaced with new oil after flushing old particles out.

Q: Do your Packard engines have a hydraulic gear change

arrangement of oil operated clutches to increase the superchargers RPMs kind of like a low and high speed for the supercharger?

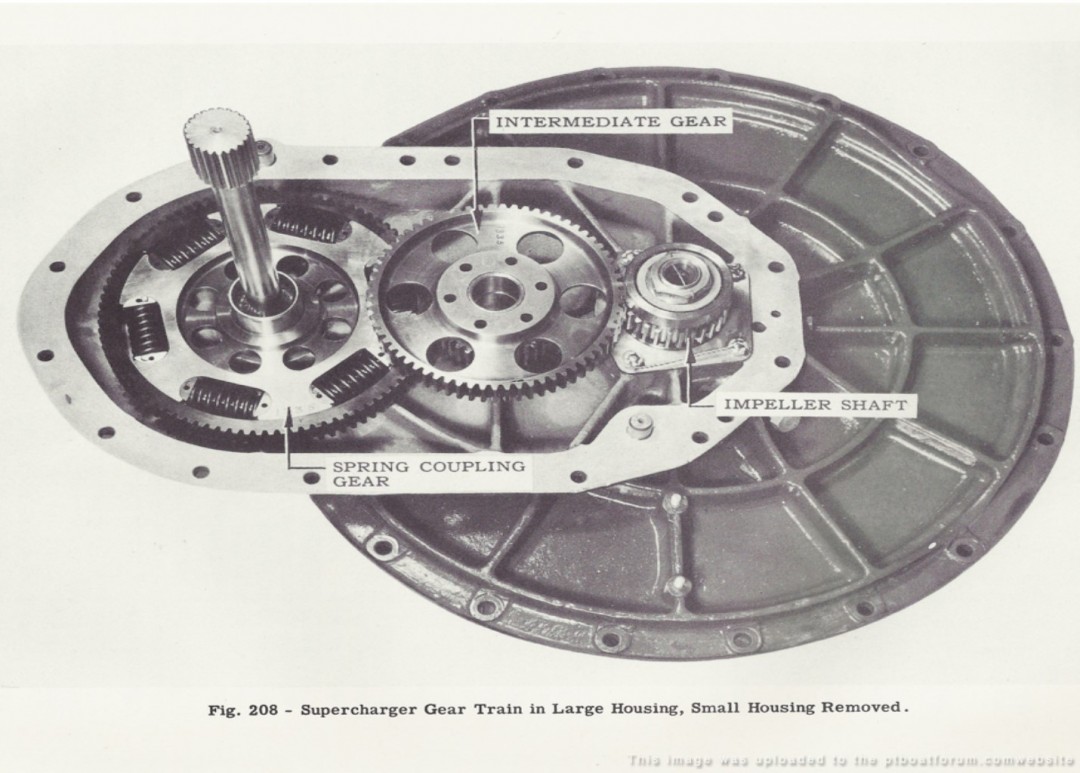

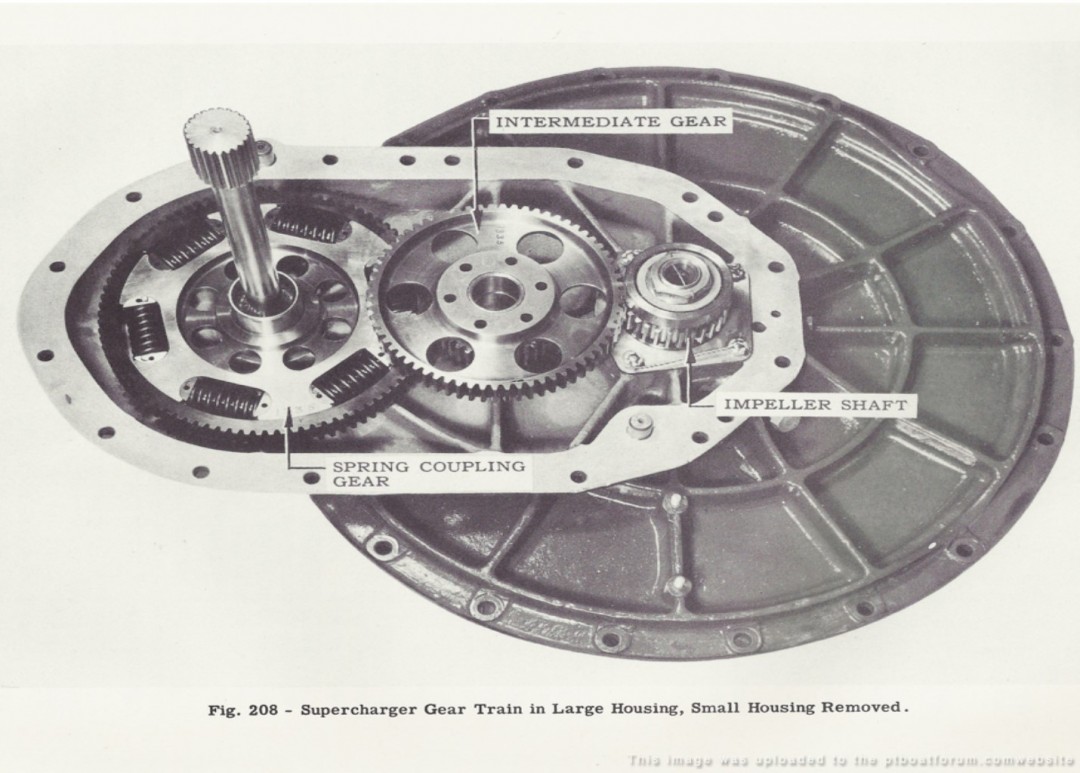

A: No, the supercharger is driven by gears as pictured below. I am familiar with on high performance aircraft engines have multiple speed turbo superchargers on them, but we only have the single speed direct gear driven style. Also, the engine output transmission gears are the original "Joes Gears" (Snow Nabstedt) used on original PT Boats. For a very short time in 2004-2005 we had some pneumatically operated gear shifting cylinders but soon removed them because the Skipper was over shifting the engines and causing premature clutch wear and failure of the reverse gear. So the pneumatic shifters were removed in 2005.

Q: Have you checked compression in each cylinder?

A: I am sure they have checked the compression, and I can get you that info as well, and as I recall it was normal compression values.

Q: Your issue sounds like torsional Vibration.

A: I will relay these concerns to our motor macks!

Meanwhile here is another photo showing the shaft and its associated gear train.

Jerry Gilmartin

PT658 Crewman

Portland OR

Posted By: Jerry Gilmartin | Posted on: Dec 5, 2021 - 8:24pm

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

Also another thought check and inspect the supercharger, if the engine backfired hard enough the supercharger can sustain damage from such event. Please send me pictures of this broken shaft when you have a chance. I do have connections with several Packard engine builders who work on everything Packard including Jay Leno's cars. Hoping to get some more answers to your problem in the coming days.

-Travis

Posted By: Travis B | Posted on: Dec 6, 2021 - 9:09am

Total Posts: 129 | Joined: Nov 23, 2019 - 10:11am

I also reached out to a Restoration shop out here in NJ that works on Packards and also has a parts department for Packards. I am hoping they can locate some more of the supercharger driveshafts for you guys. Worst case I have someone who can reverse engineer a original to make copies.

-Travis

Posted By: Travis B | Posted on: Dec 6, 2021 - 9:26am

Total Posts: 129 | Joined: Nov 23, 2019 - 10:11am

Jerry

What I noticed is the geared hub with the springs in it. You guys probably already checked this but if those springs loose tension they will stack up solid at a lower maximum torque/RPM and that may allow the connecting shaft to see a higher torque value than it was designed for. The shaft is designed to break if the engine revs too quick or the supercharger has a mechanical failure or for some reason is producing more drag/boost than it was designed for. I have noticed the same problems in high RPM engines with a manual transmission. The clutch disc has a sprung hub design similar to that on your gear. If the springs get week in the hub you loose the cushioning effect and higher shock loads are transmitted to the drivetrain. Just a thought. Good Luck!!

Thanks!

Jeff

Posted By: Jeff H | Posted on: Dec 7, 2021 - 5:49am

Total Posts: 32 | Joined: Jun 7, 2019 - 6:00am

Thanks Stearman, Jeff and Travis! I will be going down to the PT Boat house on this Thursday and will discuss these ideas with our crew. I think we have already sent the metal of the shaft out for analysis and it came back as good quality HSS, hardened on outside with core being able to "spring" like it was designed. I appreciate all of your fresh insight! We are open to any ideas that you guys may have, since the problem is sort of unusual and most of the guys who worked on these engines during WW2 have taken their "Last Patrol"

Jerry

Jerry Gilmartin

PT658 Crewman

Portland OR

Posted By: Jerry Gilmartin | Posted on: Dec 7, 2021 - 9:34am

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

Here is a photo from our latest newsletter of the most recent broken shaft next to our last unbroken spare. You can see just how much force would be required to snap this 1 inch diameter shaft like it was a twig.

Jerry Gilmartin

PT658 Crewman

Portland OR

Posted By: Jerry Gilmartin | Posted on: Dec 7, 2021 - 3:26pm

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

Jerry

From the pictures you posted it looks like the shaft end that goes into the sprung gear has an extension that fits into a bushing or bearing to locate it. On that end the splines look like they have more wear than the motor end splines. This looks like the problem is coming from the supercharger end. I would check the bearing/bushing wear on all of the gears and look for anything that has caused the gear to gear mesh to open up and cause more vibration or misalignment. From what I can see in the photo that gear looks like it is seeing a lot of vibration or back and forth speed changes. I still would check that sprung gear closely since the springs are there to dampen those type of harmonics out. My assumption is this housing is filled with gear oil for lubrication. I know this is a pain for you guys like it was for the 39 years I worked in industrial maintenance but since I retired I kind of miss it a little. Good Luck!!

Thanks!

Jeff

Posted By: Jeff H | Posted on: Dec 7, 2021 - 4:46pm

Total Posts: 32 | Joined: Jun 7, 2019 - 6:00am

this may sound like a foolish solution but what stood out to me during the discussion was that you replaced the filters with modern filters which may not be allowing enough oil supply. this is only a guess with my limited knowledge of engines. i tend to look at what changed that may be the cause of the continued problem. this may seem too simple of a solution. but worth looking at. another thought -- could a synthetic oil be used? it may give better lubrication. best of luck finding the problem. scott

Scott Campbell 2nd gen,PT 248

Ron 20

Posted By: Scott C | Posted on: Dec 7, 2021 - 5:41pm

Total Posts: 114 | Joined: Nov 20, 2019 - 4:34pm

I agree with Jeff, there has to be some sort of vibration or drag causing the shaft to break. Since the break is on the supercharger side in my opinion it has to be a issue with the supercharger or other components related to it. A bad backfire can cause damage to superchargers.

Posted By: Travis B | Posted on: Dec 8, 2021 - 7:36am

Total Posts: 129 | Joined: Nov 23, 2019 - 10:11am

Here is an old war story from the electric power plant industry. Once upon a time the Engineers at a power plant decided to upgrade four under-sized motor operated valve (MOV) actuators with a larger size. They got a really good deal on four never-installed Nuclear grade replacement MOV actuators from a company that specialized in buying surplus equipment from different industries. A while after installing these bigger actuators one of them failed. Disassembly revealed the failure of a motor pinion gear. A replacement gear was obtained by the manufacturer and they moved on. Within a few months two more of the replacement actuators failed with the same problem. The power plant mechanics replaced all of the failed gears and also replaced the same gear in the last actuator that had not failed. The mechanics noted that the last gear, removed from the still operating MOV actuator, had a different color than the three that had failed. All four gears were sent back to the manufacturer for analysis. It turned out that the original owners of these MOV actuators had “robbed” the gears to change the gear ratio on some of their other motor operated valve actuators. After obtaining the MOVs, the surplus dealer purchased one original replacement gear from the original manufacturer, and had the other three gears made at a local machine shop. The “lesson learned” for the power plant industry was “Beware when purchasing surplus or scrapped equipment. Inspect, disassemble, and take nothing for granted”.

Harvey Wheeler

Posted By: Old LeadBottom | Posted on: Dec 9, 2021 - 10:25am

Total Posts: 11 | Joined: Oct 4, 2013 - 7:36am

Update: First of all, thanks to Harvey, Scott, Travis and Jeff and everyone else for your well considered comments. I went to the boat last Thursday and met with Jack C, who has been deeply involved in wrench turning on this problem for as long as we have been trying to figure it out. I called Travis (from our Forum here) and spoke to both him and Jack while standing down in the engine room on the boat. Travis is now up to speed on what we have done, and we decided to do several things going forward.

1. Hire a professional "Vibration Monitoring Company" to come and perform baseline Vibration readings on all 3 engines while they are running, Then compare them to see if we can figure out any issues. I will be looking into doing this myself.

2. Find the specs for the supercharger components and measure our parts to see if they are in compliance with those specs. This includes the bearings and bushings and other items that affect alignment. We found the specs for everything in the Overhaul Manual and an Appendix to it.

3. Perform a more complete flush of the engine if it happens again. (last time we changed the oil filter and flushed the supercharger oil passage only).

4. Hire a machinist to manufacture 3 spare supercharger drive shafts using the same material as the originals. (Perhaps the old ones failed due to metal fatigue) This was done this week by Jack.

5. Have a metallurgy company perform a test on the failed shaft to determine the exact type of metal: DONE It was tested as SAE4340 Low Alloy Nickel Chrome Moly Steel, Quenched and Tempered for hardness and strength. We took it to a QA Laboratory and they recommended we take it to a Failure Analysis Lab (with an Electron Microscope) to determine exactly the type of failure that occurred. We are looking to do that in near future. Preliminary indications are torsional overload.

So hopefully we will learn more as we get these items knocked out. Thanks again for your help and let me know if any new ideas occur to you.

Jerry

Jerry Gilmartin

PT658 Crewman

Portland OR

Posted By: Jerry Gilmartin | Posted on: Dec 15, 2021 - 5:51pm

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

Jerry,

I would consider metal fatigue. Hard to tell from the photographs, but if the edges of the break looks like crystals that would indicate the parts fatigued. The design looks decent in that the shaft is hollow, providing more torsional strength than a wood shaft would. Would be interested in seeing a failure analysis,

Bill

Bill Smallshaw

Posted By: smallwi | Posted on: Dec 24, 2021 - 7:44pm

Total Posts: 141 | Joined: Jun 21, 2007 - 3:02pm

Hey Bill, It is a solid shaft. We are still waiting for FA results, and I will let you guys know when we get them back! Thanks and Merry Christmas!

Jerry Gilmartin

PT658 Crewman

Portland OR

Posted By: Jerry Gilmartin | Posted on: Dec 24, 2021 - 9:10pm

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

duplicate message please delete

Posted By: Jerry Gilmartin | Posted on: Dec 24, 2021 - 9:10pm

Total Posts: 1486 | Joined: Oct 8, 2006 - 11:16pm

Jerry,

I would consider metal fatigue. Hard to tell from the photographs, but if the edges of the break looks like crystals that would indicate the parts fatigued. The design looks decent in that the shaft is hollow, providing more torsional strength than a wood shaft would. Would be interested in seeing a failure analysis,

Bill

Bill Smallshaw

Posted By: smallwi | Posted on: Dec 25, 2021 - 5:54pm

Total Posts: 141 | Joined: Jun 21, 2007 - 3:02pm

Just ran across this post, so I asked my dad.

He said in his experience it was too rapid changes in engine speed that broke the driveshaft to the supercharger, if you didn't slow the engine gently the inertia from the supercharger would break the shaft. When coming into port he'd gently reduce engine speed starting about 5 miles out (and then corrected himself and said not literally 5 miles but started early very slowly reducing power). This was on 85' air force crash rescue boats with two packard v12's, during the Korean war.

Posted By: rmark | Posted on: Jan 31, 2022 - 6:50pm

Total Posts: | Joined: Unregistered

Mark,

Interesting commentary from your father. If the failure occurred when the engines were fairly new that would rule out fatigue. Certainly a rapid acceleration of the engine parts would induce higher loads. The advice to slowly advance the engine speeds makes a great deal of sense from a mechanical design perspective. Advice to PT658 skipper, no more hot ridding down the River. Slowly bring the boat up to speed and you may save yourself a few supercharger rebuilds.

Bill Smallshaw

Posted By: smallwi | Posted on: Feb 11, 2022 - 5:21pm

Total Posts: 141 | Joined: Jun 21, 2007 - 3:02pm